By definition, Autonomous Unmanned Aerial Vehicles (AUAVs) are unmanned aircrafts that are not directly ground controlled. The complete aircraft and payload mission can be defined and programmed into the vehicle during preflight set-up. The vehicle mission might include take-off, climb, cruise and loiter, as well as speed set-up, final destination position or turn-about points from global positioning satellite (GPS) coordinates, and landing coordinates.

The Condor 300 aircraft is a fully autonomous, unmanned aerial vehicle that had been developed entirely by Optimum Solutions to serve as a long-range extended loiter observation and monitoring platform.

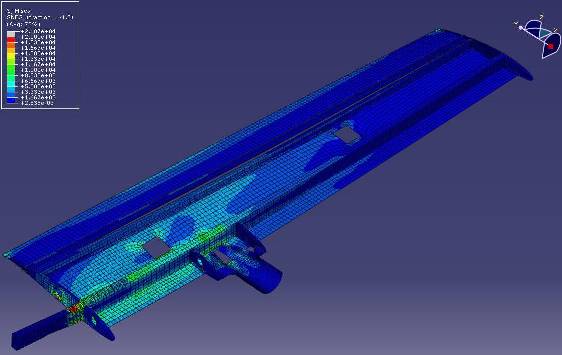

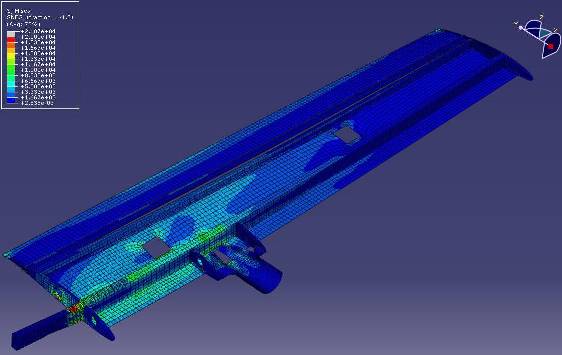

The Condor-300 electric powered aircraft features a single aerodynamically faired cylindrical fuselage riding over a low mono-wing, a “T” tail configuration and twin engines mounted on the wings. The complete airframe is constructed entirely using advanced composite material, carbon fiber embedded in epoxy resign and has been fully optimized using finite element techniques for maximum strength and minimum weight;

this produces a very strong, robust airframe at very low structural weight.

The wing and stabilizer sections are fabricated in several pieces (upper skin, lower skin, internal spars) using matched mold tooling and then bonded together to produce a lightweight structure.

The payload access, through a large hatch on the fuselage’s nose, is facilitated by the symmetric mounting of two motors on the wing's leading edge.

Condor-300’s lengthened design allowed the use of the tail dragger landing gear to augment the lateral stability of the aircraft on the ground and increase payload volume on the fuselage nose. The wings-mounted motor design eliminates fuel contamination on payloads, reduce overall vibration on payloads and produce undisturbed airflow around the fuselage nose, make it perfect for air sensors and scientific instruments installation.

Condor-300’s robust landing gear has been designed with exchangeability in mind. This extra feature allows the end-user to accommodate various main landing gear struts and wheels for different terrain operations.

The Condor-300 system is equipped with two very reliable electric motors mounted on the wings, and controlled by two powerful 60 Amps electronic speed controller. Each electric motor is equipped with a very robust gear drive box used mainly to increase torque so the motors will be able to run higher torque at lower RPM. The gear box is based on a simple planetary gear characterized by gears whose axes are not fixed. The input is through a sun gear and the output via the planet carrier which supports the planet gears.The motor and its matching gear box were fully optimized for the Condor-300 platform.

The propulsion battery system consist of a custom-built rechargeable high power polymer Li-Ion battery package developed by Optimum Solutions specific for this application. The propulsion package is easily exchange and recharge by removing a magazine-style container from the top of the fuselage.

Condor-300 design features a full redundancy on control surfaces and motors including:

The TASE and TASE Duo systems weight about a kilo and support a range of sensor options including:

Daylight Cameras:

IR Cameras:

The Condor 300 aircraft is a fully autonomous, unmanned aerial vehicle that had been developed entirely by Optimum Solutions to serve as a long-range extended loiter observation and monitoring platform.

The wing and stabilizer sections are fabricated in several pieces (upper skin, lower skin, internal spars) using matched mold tooling and then bonded together to produce a lightweight structure.

The payload access, through a large hatch on the fuselage’s nose, is facilitated by the symmetric mounting of two motors on the wing's leading edge.

Condor-300’s lengthened design allowed the use of the tail dragger landing gear to augment the lateral stability of the aircraft on the ground and increase payload volume on the fuselage nose. The wings-mounted motor design eliminates fuel contamination on payloads, reduce overall vibration on payloads and produce undisturbed airflow around the fuselage nose, make it perfect for air sensors and scientific instruments installation.

Condor-300’s robust landing gear has been designed with exchangeability in mind. This extra feature allows the end-user to accommodate various main landing gear struts and wheels for different terrain operations.

The Condor-300 system is equipped with two very reliable electric motors mounted on the wings, and controlled by two powerful 60 Amps electronic speed controller. Each electric motor is equipped with a very robust gear drive box used mainly to increase torque so the motors will be able to run higher torque at lower RPM. The gear box is based on a simple planetary gear characterized by gears whose axes are not fixed. The input is through a sun gear and the output via the planet carrier which supports the planet gears.The motor and its matching gear box were fully optimized for the Condor-300 platform.

The propulsion battery system consist of a custom-built rechargeable high power polymer Li-Ion battery package developed by Optimum Solutions specific for this application. The propulsion package is easily exchange and recharge by removing a magazine-style container from the top of the fuselage.

Condor-300 design features a full redundancy on control surfaces and motors including:

- Two independent controlled electric motors

- Two independent electric motor speed controllers

- Two independent actuators per elevator control surface

- Two independent battery supply per motor

- Two independent battery to supply servo power

Daylight Cameras:

| Camera | Image Resolution | Lens | HFOV (deg) |

| FCB-EX480C | 380K pixels | 18x Optical | 48.0°-2.8° |

| FCB-EX980 S | 640K pixels | 26x Optical | 42.2°-1.6° |

| Camera | Image Resolution | Lens | HFOV (deg) |

| FLIR / Indigo Photon | 324X256 | 19 mm;35 mmm; 50 mm | 36°;20°;14° |

| Thermoteknix 110K | 384x288 | 14.25 mm; 32 mm | 50.5°;23.7° |